Were you having a problem with your Jhon Dheere coming off or breaking? It’s likely the result of natural wear and tear, but sometimes other factors can be in play. In this blog post, we’ll explore 20 potential causes for your Jhon Dheere lasting less than it should. We’ll also provide tips on how to prevent these issues from happening again. Whether you’re an experienced user of Jhon Dheere or a first-timer, reading this post will help keep your shoe lacing well and allow you to enjoy longer use out of each pair!

- Overloading the Machine

- Improperly Installed Belt

- Not Adjusting Belt Tension

- Worn/Dry Belt

- Broken Parts

- Poor Maintenance

- Not Using the Correct Belt

- Loose Bolts & Nuts

- Incorrect Pulley Alignment

- Unbalanced Drive System

- Worn or Damaged Bearings

- Corroded Components

- Debris Stuck in the Groove of the Pulley

- Not Installing a Correctly Sized Belt

- Poor Tension

- Bad Spindle Housing Bearing

- Not Replacing The Belt Regularly

- Bad Blades

- Bad Pulley Bearing

- 20 Worn Tensioner Bracket or Spring

What are the Causes of John Deere Mower Belt Coming off?

1. Overloading the Machine

One of the most common reasons a John Deere belt keeps coming off or breaking is that it’s overloaded. This can happen if you do too much with your machine or need to apply more force on the belt when turning or cutting. To prevent this, use your John Deere machinery for what it was designed for and don’t overload it.

2. Improperly Installed Belt

If the belt is not installed correctly, it can cause slipping, eventually leading to breaking or coming off. Be sure to follow all of the instructions in your manual when installing the belt so that it fits correctly and securely.

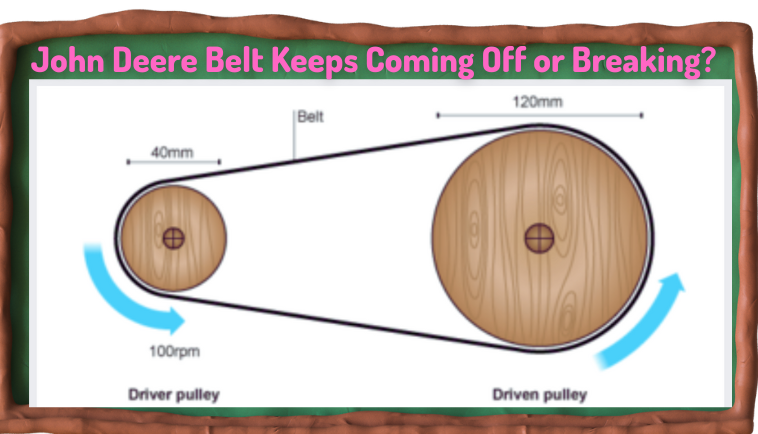

3. Not Adjusting Belt Tension

Another common cause of a John Deere belt breaking or coming off is insufficient tension. If the belt is too loose, it won’t be able to grip properly and can cause slipping or breaking. Check your manual for instructions on adjusting the belt tension and keeping it at the correct level.

4. Worn/Dry Belt

A worn or dry belt can also cause slipping, leading to a broken or coming of a John Deere belt. To prevent this, inspect your belt regularly for signs of wear and tear and use a high-quality lubricant to keep it supple and free from debris buildup.

A damaged or incorrectly installed mower belt can leave you stranded in the middle of a job. If your John Deere’s belt is looking worn and frayed, double-check that it has been routed properly around all pulleys – just one misplaced guide unpinning from its bracket could cause it to break away entirely! Consult your owner’s manual for more information on proper installation; keep yourself powered up with an intact drivebelt.

After that, if your belt is routed correctly, look for the bracket or belt guide component making contact with your deck belt.

A smooth or shiny spot forming on the metal is a good sign of which part is causing the problem. Once you find the tricky part, you require to adjust or fix it, so it no extended rubs on the belt.

You can bend a few brackets into position, while others may have a bushing that must to be replaced.

When it comes to replacing the bushings on your John Deere mower deck, you’ll need a full-on bracket assembly – and only your friendly local dealer can provide what you require. So don’t hesitate: if something’s amiss below the blades of green, get in touch with them.

5. Broken Parts

Broken parts, such as the idler pulleys, belt keepers or springs, can all cause the John Deere belt to come off or break. Regularly inspect these parts for any signs of wear and tear, and replace them if necessary.

6. Poor Maintenance

Proper maintenance is vital to keeping your John Deere in good shape. If you’re not regularly cleaning and lubricating the parts that come into contact with the belt, or checking for signs of wear, this could eventually lead to a broken or slipping belt.

7. Excess Vibration

Excess vibration from an unbalanced engine or other components can cause the John Deere belt to slip off or break over time due to excess strain on the belt. Make sure to check for and address any issues that could be causing excess vibration in your machine.

8. Loose Pulleys

The pulleys on the John Deere mower can become loose over time due to wear, which can cause slipping or breaking of the belt. To prevent this from happening, regularly inspect the pulleys and tighten them if necessary.

9. Poor Alignment

If the blades are not aligned correctly with the belt it can cause excessive strain on the belt, leading to it coming off or breaking over time. Be sure to follow all instructions in your manual when aligning your blades and Belt to synchronise them properly.

10. Worn Deck Wheels

The deck wheels on your John Deere mower can become worn over time, leading to increased friction between the wheel and belt. This can cause slipping or breaking of the belt and should be addressed with new deck wheels as soon as possible.

11. Oil or rust on the belt

Oil or rust on the belt can cause it to slip, eventually leading to a broken John Deere belt. Make sure to clean off any oil or rust from the belt and pulleys regularly, and use a high-quality lubricant on them. This will help keep your mower running smoothly.

12. Age

Finally, age is an essential factor in belts for John Deere machines. Over time, belts can become worn out due to wear and tear, so check the age of your belt and replace it if necessary. Doing this will ensure that your machine runs smoothly in the future.

13. Debris stuck in the groove of the pulley

Another reason is debris stuck in the groove of the pulley can cause slipping or coming off of the John Deere belt. Make sure to regularly inspect and clean out any debris from the pulleys so that they remain free from obstructions, allowing the belt to move freely.

14. Not Installing a Correctly Sized Belt

John Deere belts come in many different sizes, so it’s essential to make sure you install one with the right size for your machine. Installing a belt that is too large or too small can cause slipping or breaking due to improper fitment. Always double-check your manual for the correct size when replacing your John Deere belt.

15. Poor Tension

Adjust the tension properly when installing a new belt, so it is neither too tight nor too loose. If the belt is too loose, this can cause slipping and coming off of the John Deere belt due to inadequate friction between the pulley and belt. And if it’s too tight, this can lead to excessive wear on both the pulleys and belt, eventually resulting in breakage or coming off of the belt.

16. Bad spindle housing bearing

The spindle housing bearing can become worn out over time, resulting in poor alignment between the pulleys and belt. A bad approach can also lead to increased friction between the pulleys and belt, which can cause slipping or breaking of the John Deere belt. Replace any damaged bearings immediately to ensure your mower functions appropriately.

17. Not Replacing The Belt Regularly

Depending on usage, John Deere belts should be replaced every few years, so check yours regularly and replace it if necessary. This will help extend the lifespan of your machine and prevent unexpected breakdowns due to a worn-out or broken John Deere belt.

18. Bad Blades

If the blades on your John Deere mower are not sharp or in good condition, they can cause excessive strain on the belt resulting in it coming off or breaking. Make sure to inspect and replace worn-out blades regularly to keep your machine running smoothly.

19 Bad pulley bearing

If the pulley bearings are bad or worn out, they can cause increased friction between the belt and the pulleys, leading to slipping or breakage of the Belt. Inspect the bearing regularly and replace any damaged ones as soon as possible.

20. Worn tensioner bracket or spring

The tensioner bracket or spring is an essential component of your John Deere mower, as it helps keep the belt in proper alignment and at the correct tension. If worn out or damaged, this component can cause improper tension on the belt, leading to slip-off or breakage. Inspect this component regularly and replace any broken parts as soon as possible.

That completes our list of common causes of slipping or breaking a John Deere belt. Keeping these things in mind, you should be able to prevent any unexpected problems and keep your machine running smoothly for many years!

How To Take Care of My John Deere Mower?

Following these steps will help extend the life of your Jhon Deere belt and keep it from falling off:

- Clean your mower deck after each mowing to remove debris, clippings and other obstructions that may be preventing the belt from gripping the pulleys properly.

- Periodically check for any signs of wear and tear on the belt.

- Clean all your pulleys to make sure they are free from debris and rust.

- Make sure that your spindle housings are in good

- condition.

- Check your idler tensioner bracket or spring to make sure it is not worn or broken.

- Keep your mower belt lubricated with a high-quality belt lube.

- Replace any parts on your John Deere that may be worn or broken.

- Follow the manufacturer’s instructions when installing your belt.

In Summary

John Deere deck belts can be pricey, but with proper maintenance and regular inspections for wear and tear, you can keep your belt running smoothly for a long time. If you do find yourself needing to replace the belt on your John Deere mower, make sure that you follow all of the steps outlined in this article before you begin. With the right tools and knowledge, replacing your John Deere deck belt can be a breeze.

Your John Deere Mower Deck Can Cause an Uneven Cut

Many components on your John Deere mower deck can cause an uneven cut. If any of these components are bent, worn out or broken, they will cause the blade to cut unevenly. Inspect your deck regularly and replace any damaged parts with genuine John Deere parts so that you get a quality even cut every time. This will help extend the lifespan of your machine and ensure you get the best performance possible.

Still, Need Help with Your John Deere Lawn Mower?

As a John Deere mower owner, you will encounter various problems over the mower’s life. These can include issues with starting, dying while mowing, vibrating, cutting unevenly, and not moving.

To help you identify why your mower is having problems, I compiled a handy guide to help you troubleshoot your John Deere. Check out 12 REASON JOHN DEERE MOWER WON’T START [PROBLEM & SOLUTION]

Douglas Mackalie is a Founder of Mackalies Garden. He is one of the most exciting people you’ll ever meet. He has 25 years of experience in horticulture and gardening, most of which he’s spent outdoors getting his hands dirty.